- HOME

- ABOUT GOOGOL

- PRODUCTS

DIESEL ENGINE

GENERATOR SETS

- DOWNLOAD

- CASES

- NEWS

- CONTACT US

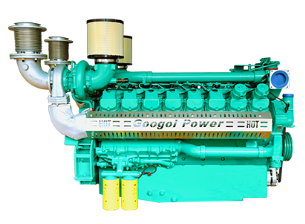

DIESEL ENGINE

GENERATOR SETS

The process of diesel combustion in the engine to generate power is mainly divided into the following stages:

Firstly, the intake stroke. At this stage, the piston moves from top dead center to bottom dead center, the intake valve opens, and the exhaust valve closes. As the piston descends, negative pressure is generated inside the cylinder, drawing air into the cylinder. Due to the fact that only air enters the cylinder during the intake process of diesel engines, the intake volume is relatively large, which also provides sufficient oxygen for the subsequent combustion process.

Next, the compression stroke. The piston moves from bottom dead center to top dead center, and both the intake and exhaust valves are closed. During this process, the air inside the cylinder is compressed, causing a sharp increase in pressure and temperature. The compression ratio of diesel engines is relatively high, usually between 16:1 and 22:1, which compresses the air to a very high temperature, typically up to 500 ℃ to 700 ℃.

Then, perform the power stroke. When the piston approaches the top dead center, the fuel injector injects diesel into the cylinder with extremely high pressure. Due to the high temperature inside the cylinder at this point, far above the self ignition temperature of diesel (about 200 ℃ to 300 ℃), diesel quickly atomizes and self ignites. The combustion of diesel is a type of diffusion combustion, in which diesel vapors mix with air and ignite and burn on their own under high temperature and pressure. The high-temperature and high-pressure gas generated by combustion drives the piston downward, and through the connecting rod, drives the crankshaft to rotate, thereby converting the chemical energy of the fuel into mechanical energy and generating power.

Finally, the exhaust stroke. The piston moves from bottom dead center to top dead center, the exhaust valve opens, and the intake valve closes. After the power stroke is completed, the exhaust gas in the cylinder is discharged from the cylinder under the push of the piston, preparing for the next cycle.

Overall, the combustion process of diesel in an engine is a complex physicochemical process. Through the continuous cycle of intake, compression, power generation, and exhaust, diesel engines continuously convert the chemical energy of diesel into mechanical energy, providing power for various mechanical equipment. At the same time, in order to ensure the efficient operation of diesel engines, precise control and optimization of the fuel injection system, intake system, exhaust system, etc. are also required to ensure that diesel can burn in the appropriate way at the appropriate time and place, thereby maximizing the performance and efficiency of the engine.